|

|

|

|

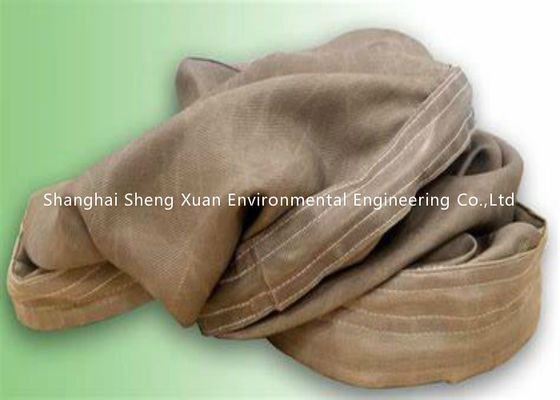

Fire Retardant Calendering PTFE Reverse Air Bag Filter

|

Product Details:

Payment & Shipping Terms:

|

| Material: | Fiberglass Filter Fabric | Scrim: | 100% Fiberglass Woven Fabric Scrim |

|---|---|---|---|

| Bag Size: | DN 292x 10000mm | Work Temp.: | 280 Degree |

| Air Permeability: | 15-30 M3/m2.m | Application: | Alloys Furnace |

| Name: | Fiberglass Dust Filter Bag | Filtration Efficiency: | < 20mg/Nm3 |

| Life: | 12 Months | Treatment: | PTFE Dipping And Coating |

| High Light: | Calendering Reverse Air Bag Filter,PTFE Reverse Air Bag Filter,Fiberglass Reverse Air Bag Filter |

||

Reverse Airbag House Bag Filter

When it comes to filter bag construction there are a wide variety of configurations. The simplest way to understand the top and bottom construction needed for your filter bag will be knowing the type of dust collector system you have. There are three common types of baghouses; pulse-jet and plenum pulse, reverse air, and shaker.

Pulse-jet and plenum pulse baghouses are the most widely used style of dust collector. They can be configured as either top load or bottom load. If your baghouse is top load the most common filter bag construction is a double beaded snap band top with a disc bottom. If you have a bottom load baghouse the most common construction is a raw top with disc bottom.

Reverse air baghouses are typically seen in large air handling applications. The most common filter bag configuration is a compression band with cap and hook for the top. For bottom configuration you will typically see either a compression band, corded, or double beaded snap band.

Shaker baghouses are generally simple and can be seen in applications where there is no compressed air available. In shaker baghouses the filter bags are hung and tensioned from the top of the unit, and at the bottom they are attached to a tube sheet. The most common top configurations are grommet top, loop top and strap top. Bottom configurations can range from corded cuff or a double beaded snap band.

How to choose the filter bag ?

The filter bag plays a key role in the dust-cleaning process, so it is very important to do the filter selection, which should be based on its performance and the nature of the smoke, so as to have a rational and optimized scheme.

The Factors that affecting the selection of the filter medium

The Select Indication of the Filter medium

A. Temperature

B. Chemical Property

C. Concentration of the dust content

D. Filter Gas Speed

Test Item & Test Standard

| SL.No. | Item | Test Standard |

| 1 | Area Weight | FZ/T60003-91 |

| 2 | Air Permeability | GB/T5453-1997 |

| 3 | Tensile Strength | GB/T3923.1-2013 |

| 4 | Elongation | GB/T3923.1-2013 |

| 5 | Burst | GB/7742.1-2005 |

| 6 | Liquid Repellent | GB/4745-2012 |

Post Treatment For Filtering Materials

Singeing, calendaring,Heat setting

Water and oil repellent

PTFE Dispersion treatment

PTFE surface Coating treatment

Fire Retardant treatment

Package detail and Delivery time

Samples delivery time : 1 ~ 2 days

Normal products : Available stock

LCL orders delivery time : 7~10 days

FCL orders delivery time : 15~20 days

Shipping way & Loading Port :

By sea / air / express

Shanghai / Ning Bo/Tianjin

Applications:

Steel,Metallurgy,Cement,Carbon black,Thermal Power,Asphalt mixing, waste incineration.

Technical Service &support

Provide Solutions

Offer further technical support with extensively qualified experience

Provide Senior Technical staff for on site technical support

Professional Recommendations on dust collector operation and maintenance

Professional Supervision of filter bag installation

Laboratory analysis of the condition of used filter bags and recommended solutions for optimum performance

Analysis of filter bag life and recommendations of replenishment programs

Contact Person: Mr. Zhang

Tel: +8613917877783

-

Non Woven Nomex / Polyester Filter Bag

-

Coal mining Use Dust Collector Filter Bags

-

Asphalt Mixing Plant Nomex Filter Bags

-

Oil And Water Resistance Polyester Filter Bag With Fire Retardant Treatment

-

100% Fiberglass Scrim Industrial Dust Filter Bags Widely For All Kinds Dust Collectors

-

280 Degree PTFE Dust Collector Filter Bags